Highland's products include hydraulic pumps, motors, hydraulic test benches, and portable hydraulic testers. These hydraulic pumps and motors largely incorporate technology from Sundstrand's PV20 variable piston pumps and MF20 motors, allowing for interchangeable connection dimensions and performance parameters, with a rated pressure of up to 42 MPa. They are designed to deliver both strength and flexibility to meet your needs.

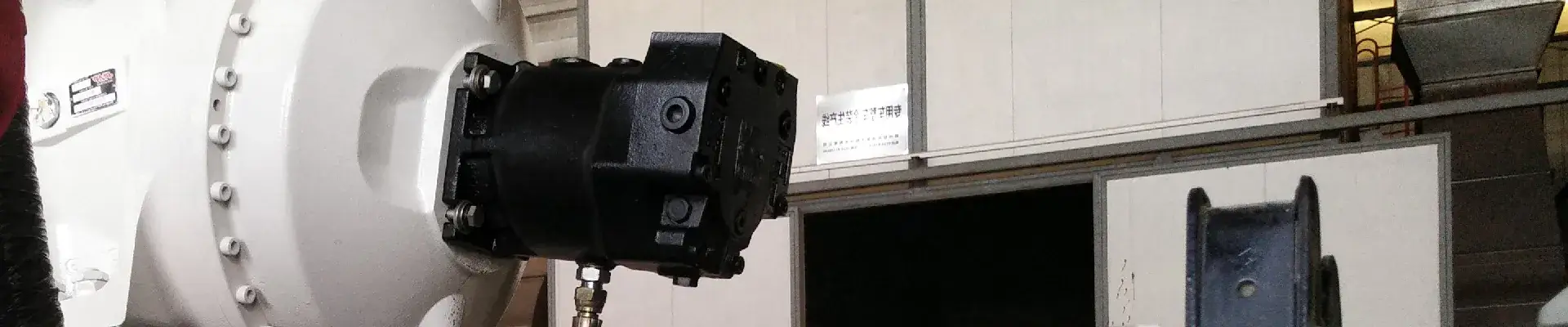

The Highland Hydraulic Test Bench is a modular, high performance solution designed for factory and type testing of hydraulic pumps, motors, cylinders, valves, and valve groups.

A simple and reliable way to diagnose hydraulic system issues on-site is our portable hydraulic tester. It is your go-to tool for identifying faulty components quickly and accurately.

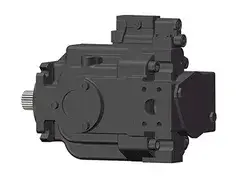

The closed-circuit piston motors are designed for closed hydraulic systems, providing flexible control, a convenient layout, strong overload protection, and a compact design. These features make them highly applicable across construction, agricultural, and mining machinery. Highland’s closed-circuit piston motors are your ideal choice for robustness and reliability.

Axial piston pumps stand out for their adjustable flow rates and high-pressure capabilities, ensuring stable and continuous hydraulic support in challenging environments like heavy industry, mining, and agricultural applications. Our axial piston pumps are designed to meet these specifications, ensuring outstanding performance for your equipment.

In addition, hydraulic component testing is at the heart of hydraulic technology, and our hydraulic test bench is a key product. It provides complete testing solutions for both individual components and the overall performance of hydraulic systems. Our test benches can be used to test pumps, motors, valves, cylinders, and other parts to ensure they perform reliably under tough conditions. With over 20 years of experience and continuous innovation, Highland has developed expertise in producing customized hydraulic test benches. We offer both standard and tailored products to meet the specific testing and maintenance needs of different industries.

Connect with us today to discover how our products can boost your equipment’s performance and reliability. Let’s make your operations stronger together!

Frequently Asked Questions

Frequently Asked QuestionsA hydraulic pump is a primary component that converts mechanical energy into pressure energy, making it easier to transfer power by driving fluid under pressure. It is commonly used in industries like agriculture and oil production.

A hydraulic motor operates on the same basic principle, but instead of using pressure to move fluid, it uses fluid pressure to drive a mechanical shaft, creating rotational force. Essentially, a hydraulic motor converts hydraulic energy back into mechanical energy.

In industrial applications, there are many types of hydraulic pumps. The three most common types are: the power source based, the pump action based and the positive displacement pumps.

A hydraulic pump is the power source in a hydraulic system, determining the system’s pressure and flow rate. Selecting the right pump involves considering the required pressure, flow rate, cost, stability, and accuracy of the system. It’s also essential to weigh the advantages and disadvantages of each pump type before making a final choice.

Compared to open-circuit systems, closed-circuit hydraulic systems offer the following advantages: