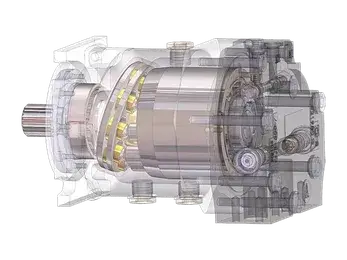

The HMF closed circuit axial piston motor is designed to deliver enhanced performance and flexibility, building on the trusted TM89 motor. With adjustable high-pressure relief options of 35 MPa and 42 MPa, this motor can be configured with two different components within the same housing, offering you two displacement choices. Plus, the standardized mounting collar and optional spline connection give you flexibility in installation.

| Model | HMF30 | HMF50 | HMF70 | HMF90 | HMF110 | HMF130 | ||

| Displacement | Rated displacement | 30 | 50 | 70 | 90 | 110 | 130 | |

| Max. displacement | ml/r | 30 | 50 | 70 | 90 | 110 | 130 | |

| Rotation Speed | Max. continuous working speed (full load) | r/min | 3200 | 3200 | 3200 | 3000 | 2700 | 2700 |

| Max. working speed (instantaneous) | r/min | 3800 | 3500 | 3200 | 3200 | 2900 | 2900 | |

| Rated speed | r/min | 2500 | ||||||

| Min. continuous working speed | r/min | 500 | ||||||

| Pressure | Rated pressure | Mpa | 35 | |||||

| Max. pressure (instantaneous) | Mpa | 38 | ||||||

| Continuous working pressure (△P) | Mpa | 30 | ||||||

| Max. permissible housing pressure (absolute) | Mpa | Constant 0.25 Peak value 0.5 | ||||||

| Torque | Continuous output torque (under continuous working pressure) | Nm | 143 | 248 | 334 | 430 | 526 | 621 |

| Max. output torque | Nm | 167 | 278 | 390 | 502 | 613 | 725 | |

| Power | Max. power | kW | 56 | 93 | 131 | 157 | 180 | 212 |

| Temperature | Permissible housing temperature | ℃ | -40 to 50 | |||||

| Max. working temperature of oil tank | ℃ | 80 | ||||||

| Weight | Hydraulic motor weight (without hydraulic oil) | kg | 22 | 23 | 33 | 34 | 36 | 38 |

Speak directly to our experienced engineer by emailing or giving a call. Alternatively you can fill the form and we will be in touch with you as soon as possible.

A hydraulic motor converts fluid pressure into rotational motion. Pressurized fluid from a hydraulic pump moves the motor’s gears, pistons, or vanes, turning the motor's output shaft.

The three main types of hydraulic motors are gear motors, piston motors, and vane motors.

In a piston hydraulic motor, pistons are connected to a shaft via connecting rods. When fluid enters the motor, the pistons move up and down in the cylinder, causing the shaft to rotate. Piston motors are commonly used in construction equipment because they generate high torque.

There are two common types of piston hydraulic motors: axial piston motors and radial piston motors.

An axial piston motor is one of the most commonly used types of hydraulic motors. It works by using a series of pistons in a cylinder block to create linear motion, making it ideal for hydraulic systems that require high torque, such as construction equipment.

Hydraulic motors are among the most versatile and widely used motors in the world. They’re suitable for applications ranging from small household devices to large industrial machinery. The main benefits of using hydraulic motors include:

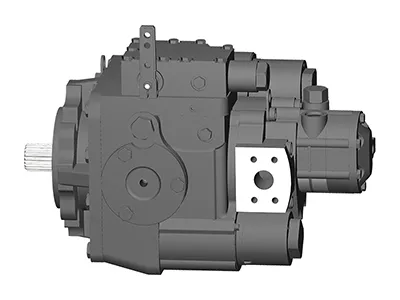

Highlands’s axial piston pumps are built for top performance in the toughest environments to deliver the power and adaptability needed for your equipment.

Built for reliability in the toughest conditions, our hydraulic piston motors combine high-quality materials with advanced manufacturing techniques to deliver stable performance.

The Highland Hydraulic Test Bench is a modular, high performance solution designed for factory and type testing of hydraulic pumps, motors, cylinders, valves, and valve groups.

A simple and reliable way to diagnose hydraulic system issues on-site is our portable hydraulic tester.