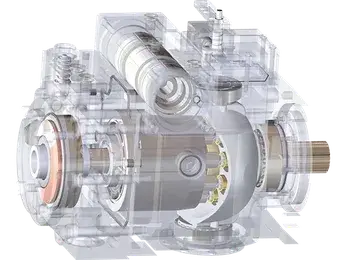

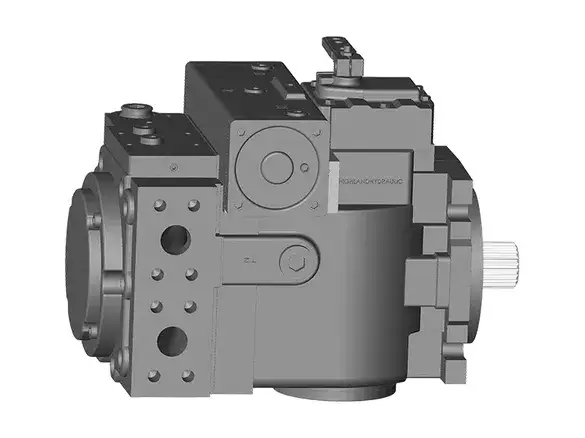

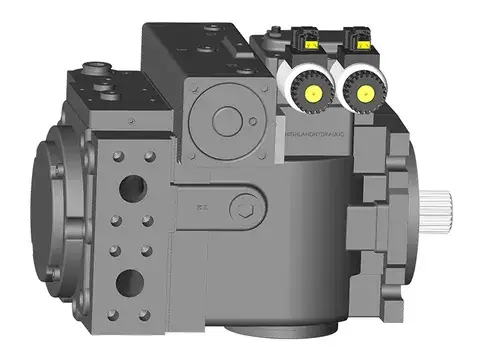

The LPV series closed circuit axial piston pump is designed to deliver stability and power, drawing from the proven SUNDSTRAND 90 series design and adding innovative features like pressure cut-off protection and customizable options to fit your exact needs. Plus, with interchangeable parts that align with our HPV series, maintenance and servicing are straightforward and efficient.

The LPV Series is versatile across many applications:

| Model | LPV30 | LPV50 | LPV70 | LPV90 | LPV110 | LPV130 | LPV160 | LPV180 | LPV200 | ||

| Displacement | Rated displacement | 30 | 50 | 70 | 90 | 110 | 130 | 160 | 180 | 200 | |

| Max. displacement | ml/r | 33.3 | 51.6 | 69.8 | 90.5 | 110.8 | 130 | 160 | 180 | 200 | |

| Rotation Speed | Max. continuous working speed (full load) | r/min | 3500 | 3500 | 3200 | 3000 | 2900 | 2700 | 2400 | 2400 | 2400 |

| Rated speed | r/min | 2500 | 2200 | ||||||||

| Min. continuous working speed | r/min | 500 | |||||||||

| Pressure | Rated pressure | Mpa | 35 | ||||||||

| Max. pressure (instantaneous) | Mpa | 42 | |||||||||

| Continuous working pressure (△P) | Mpa | 30 | |||||||||

| Max. permissible housing pressure (absolute) | Mpa | Constant 0.25 Peak value 0.5 | |||||||||

| Torque | Continuous output torque (under continuous working pressure) | Nm | 162.3 | 252.3 | 342.6 | 432.9 | 535.3 | 632.4 | 776 | 875 | 972 |

| Max. output torque | Nm | 227 | 353 | 480 | 606 | 749 | 885 | 1000 | 1098 | 1200 | |

| Power | Continuous power | kW | 41 | 72 | 98 | 128 | 137 | 162 | 191 | 224 | 279 |

| Max. power | kW | 57 | 87 | 105 | 138 | 159 | 188 | 292 | 307 | 318 | |

| Temperature | Permissible housing temperature | ℃ | 80 | ||||||||

| Max. working temperature of oil tank | ℃ | 70 | |||||||||

| Weight | Hydraulic pump weight (without hydraulic oil) | kg | 44 | 45 | 62.5 | 63.5 | 71 | 96 | 98 | 140 | 144 |

Speak directly to our experienced engineer by emailing or giving a call. Alternatively you can fill the form and we will be in touch with you as soon as possible.

A hydraulic pump works by using mechanical energy to pressurize fluid within a closed system. The pressurized fluid is then used to power machinery like excavators, presses, and lifts.

There are two main types of hydraulic piston pumps: axial and radial. Both types can be fixed or variable displacement. A fixed displacement pump moves a set amount of fluid each cycle, while a variable displacement pump can adjust the amount of fluid moved per cycle.

Choosing the right hydraulic pump depends on an assessment of your application. Consider the required pressure, flow rate, speed, horsepower, and the type of fluid used. Radial piston pumps can handle a variety of fluids, including mineral oil and water-glycol hydraulic fluids, while axial piston pumps are preferred for high-pressure applications.

Compared to gear pumps and vane pumps, piston pumps offer distinct advantages:

Overall, piston pumps stand out for their high pressure, compact structure, efficiency, and ease of flow adjustment, making them widely used in high-pressure, high-flow applications such as hydraulic presses, construction machinery, and marine equipment.

Highlands’s axial piston pumps are built for top performance in the toughest environments to deliver the power and adaptability needed for your equipment.

Built for reliability in the toughest conditions, our hydraulic piston motors combine high-quality materials with advanced manufacturing techniques to deliver stable performance.

The Highland Hydraulic Test Bench is a modular, high performance solution designed for factory and type testing of hydraulic pumps, motors, cylinders, valves, and valve groups.

A simple and reliable way to diagnose hydraulic system issues on-site is our portable hydraulic tester.